SF Welding Export for Creo

Automate the programming of welding robots for lot size 1

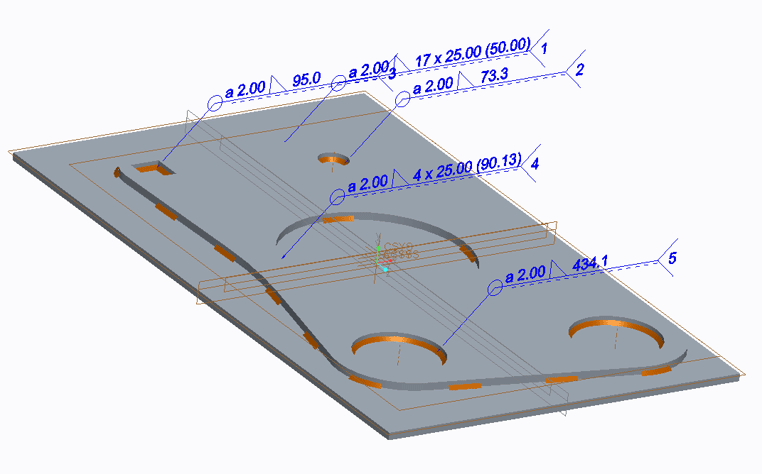

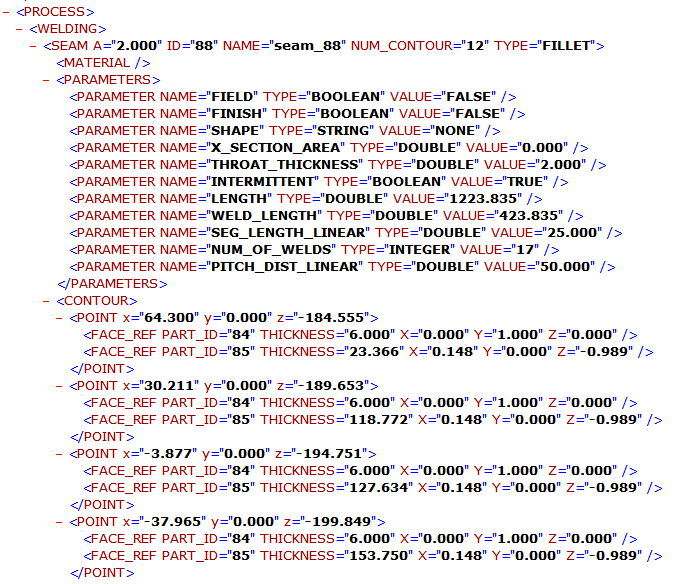

Robot-based welding with small lot sizes and changing product variants is often uneconomically and the welding processes are performed by welders manually. However, qualified personnel is becoming scarce since welding is also feeling the impact of skill shortage. A continuous digital transformation of the process chain from development to manufacturing with SF WELDING EXPORT for PTC Creo can solve this problem. With this software, a “digital shadow”, a virtual and real-time model of the product and the welding product, is available at any time.