The Plus in Production Management (MES) Based on a Digital Twin

How do you implement a transparent, flexible and extensible MES solution?

Start and visualize reality virtually!

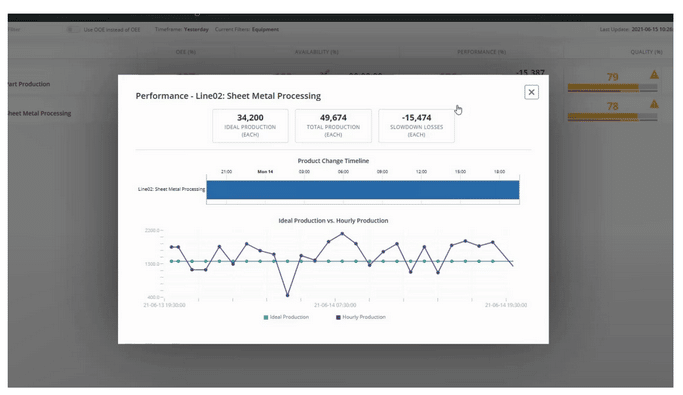

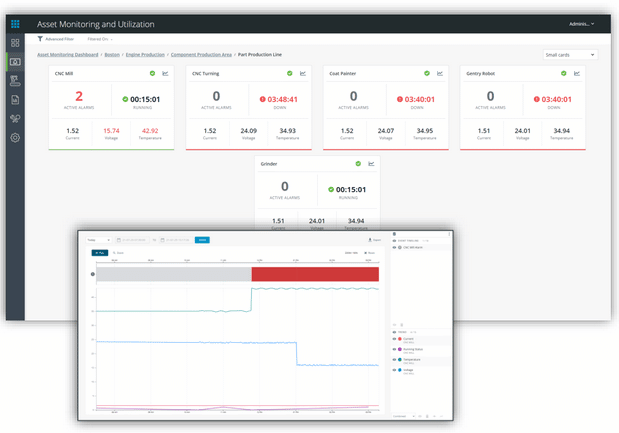

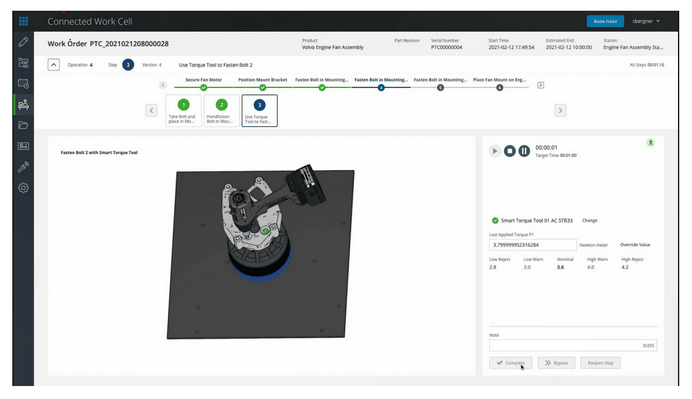

Transparency, quality and efficiency in the production process as well as the subsequent process steps in service and maintenance, are all essentially a question of information and data.

The focus is on the needs-based processing of production and operating data as well as an intelligent process control that supports the existing competitive advantages. Our solutions range from simple data acquisition and visualization to comprehensive Manufacturing Execution Systems (MES) for the entire enterprise.